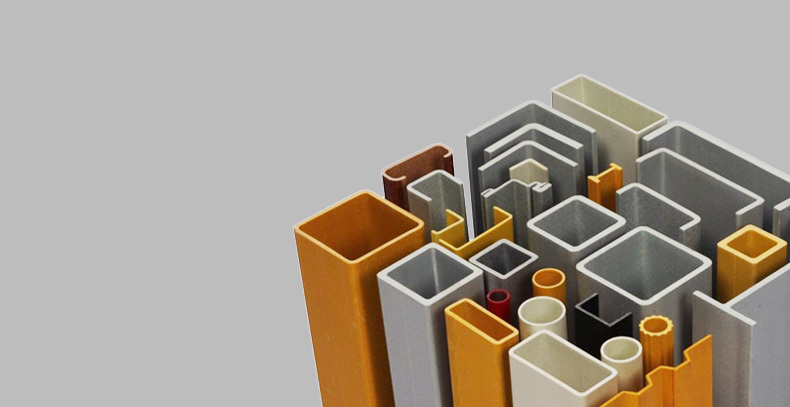

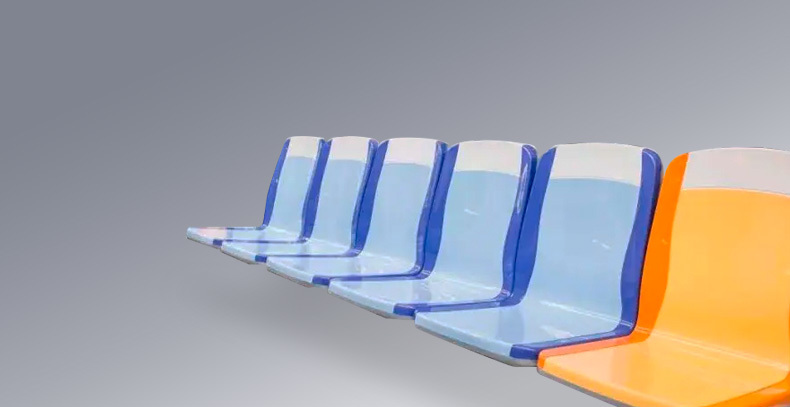

With FRP radome and bus air conditioning shell as the leading products, FRP profiles, carbon fiber profiles

FIND THE IDEAL PRODUCTS FOR YOU

VIEW MORE →Jiangsu Longcheng FRP Co.,Ltd.

Jiangsu Longcheng Frp Co., Ltd.(the Original Factory is Yixing Huadong Frp General Factory) Was Founded in 1976, Which is the Member of China Composites Industry Association, Director Member of China Composites Association.

With advanced management concept, strong technical strength and forward-looking thinking, the company has gradually formed a product system with three major plates of pultrusion, hand paste and carbon fiber, with FRP radome and bus air conditioning shell as the leading products, FRP profiles, carbon fiber profiles and other categories of common development products.

To expand the international market, a new production base has been established in Mumbai, India

Pre-sale Service

Free samples are available, but the clients have to undertake the transportation fees. Also, we can customize the products according to the samples provided by the clients. We offer OEM service.

View more →

Production Cycle

The goods in stock will be delivered within 2 to 3 workdays since the order is placed. Delivery time of custom-made products is determined according to the raw materials, standards, quantity, production technology, and the like. In general, customized products will be delivered after 15 to 30 workdays. For product specifications and production cycles, please consult our sales personnel.

View more →

Quality Control

Prior to the delivery, we welcome the clients to come to our factory for checking the goods quality. For those clients who are inconvenient to come, we will clearly state the quality assurance items in the contract.

View more →

After-sale Service

60 days quality warranty time will be offered. If the product has any quality problem during the period, our company will compensate it for free.

View more →

Fully implemented and implemented ISO 9001:2015, products are exported to more than 30 countries

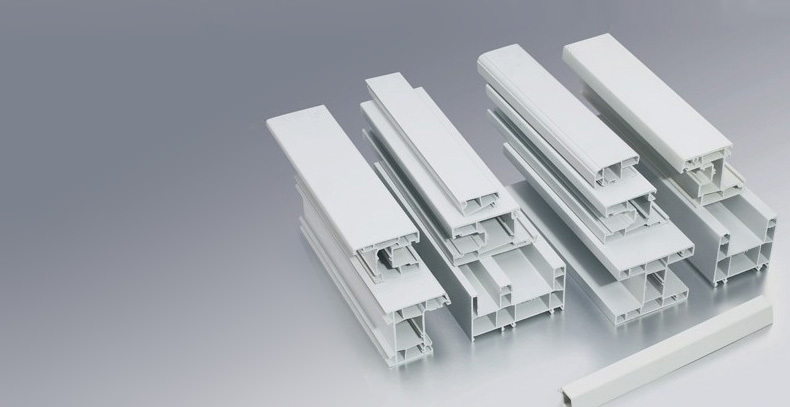

What are the FRP profile products?

Construction industry: cooling tower, glass fiber reinforced plastic doors and windows, building structure, enclosure structure, indoor equipment and decorative parts, glass fiber reinforced plastic flat plate, corrugated tile, decorative plate, sanitary ware and integral toilet, sauna, surfing bathroom, building construction template, warehouse building, solar energy utilization device, etc. Chemical industry: corrosion-resistant pipes, storage tanks and tanks, corrosion-resistant transfer pumps and their accessories, corrosion-resistant valves, grilles, ventilation facilities, sewage and wastewater treatment equipment and its accessories, etc. Automobile and railway transportation industry: automobile shells and other parts, full plastic mini cars, body shells, doors, inner plates, main columns, floors, bottom beams, bumpers, instrument panels of large passenger cars, small passenger and freight cars, and cabs and machine covers of fire tank cars, refrigerated vehicles, tractors, etc; In terms of railway transportation, there are train window frames, roof bending plates, roof water tanks, toilet floors, luggage car doors, roof ventilators, refrigerated doors, water storage tanks, and some railway communication facilities; In terms of highway construction, there are traffic signs, road signs, isolation piers, highway guardrails, etc.

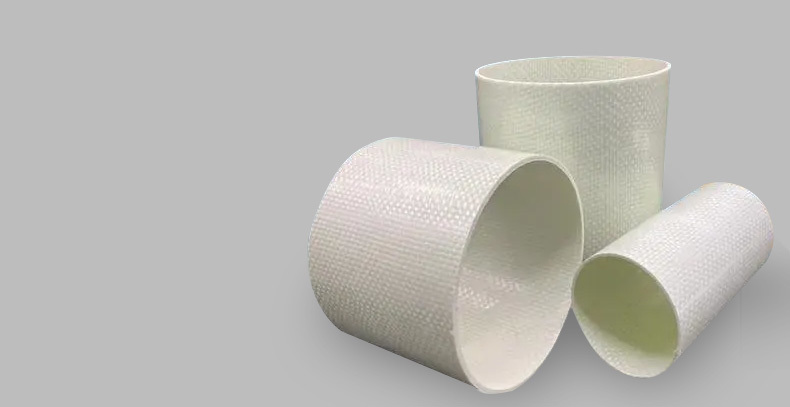

Why can FRP profiles prevent corrosion?

The corrosion resistance of FRP profiles mainly depends on the resin. The less functional groups in the resin, the less active and the more stable the resin. For example, ester groups are easy to be dissolved by alkaline water, amide groups are easy to be dissolved by acid, polar bonds such as C-O and C-N are easy to hydrolyze, and C-H is easy to be oxidized. These are chemical actions. It is also related to glass fiber, filler, curing agent and surface treatment agent. In addition to chemical or physical effects on glass fiber and resin, chemical media also play a role in its interface bonding, leading to the destruction of FRP properties. Therefore, reasonable selection of materials and improvement of resin crosslinking density are the key to manufacturing corrosion resistant FRP. The three factors, temperature, concentration and resin type, which play a dominant role, can only be determined according to the specific situation.

What is the material of FRP profile

There are many kinds of FRP pultrusion profiles, including FRP round tubes, FRP square tubes, FRP rectangular tubes, FRP round rods, and FRP I-beams. The basic components of pultruded FRP profiles are resin and glass fiber (including cloth, felt, etc.). It uses fiber (including glass fiber, carbon fiber, organic fiber and other metal and non-metallic fibers) as reinforcement materials, and resin (mainly epoxy resin, polyester resin, phenolic resin) as binder, It is compounded with other auxiliary materials (main auxiliary materials: release agent, curing agent, catalyst, sealing agent, UV light stabilizer, mold cleaning water, gel coat, etc.). It has a series of excellent characteristics such as high temperature resistance, corrosion resistance, high strength, small specific gravity, low moisture absorption, small extension and good insulation